Discover what lies beneath the surface with Reveal’s suite of concrete scanning technology.

Concrete Scanning Gold Coast

An affordable solution

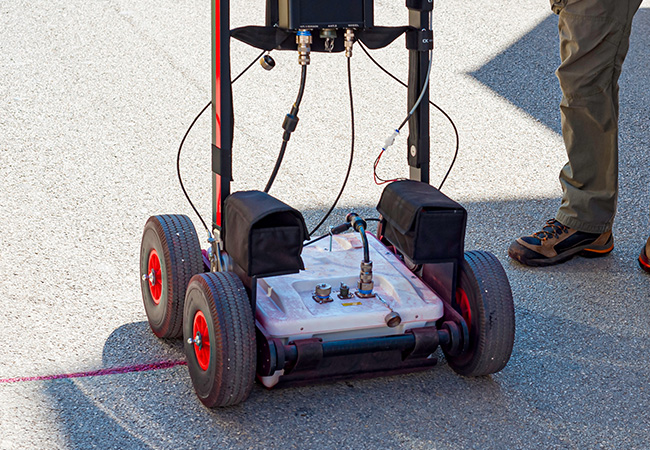

By utilising our state-of-the-art GPR scanning and EMF reading technology for your concrete testing needs, you are able to save a chunk of time and money on your project.

As a result of doing your due diligence in locating underground services, it is also far more likely that you will not strike any utilities and be liable for any problems, injuries or damages caused by concrete cutting or drilling.

Our team is also highly experienced in concrete scanning, and as a result can provide a high-quality, time-effective service that fits your budget.

Accurate concrete investigation and scanning

At Reveal Underground Services, we have the facilities to offer a quicker, safer, and more cost-effective way to scan concrete in comparison to traditional radiographic testing methods or destructive testing. We perform this service across every region we service, including the Gold Coast, Brisbane, Sunshine Coast, Ipswich, Logan, and greater Melbourne areas.

To discover more about the vast range of excavation and location services offered by Reveal Underground Services, be sure to visit our services page today.

If you are after an obligation-free quote on our concrete scanning services, be sure to get in touch by calling 1300 REVEAL or by contacting us.

Frequently Asked Questions

The accuracy of concrete scanning depends on several factors, such as the type of scanning technology used, the quality of the equipment, and the skill and experience of the operator. In general, modern concrete scanning technologies can provide highly accurate results, often within a few millimeters.

Concrete thickness can be measured using non-destructive testing techniques, such as Ultrasonic Pulse Velocity (UPV), Ground Penetrating Radar (GPR), Impact Echo Testing (IET), and Half-cell potential test. These methods use ultrasonic waves, radar waves, vibrations, and an electrical potential to estimate the thickness of the concrete. The appropriate method depends on factors such as the type of concrete and the accuracy required. A trained professional should be consulted to determine the most suitable method.

Ground-penetrating radar (GPR) is a device that can see through concrete. GPR is a non-destructive testing method that uses high-frequency electromagnetic waves to image the subsurface. The radar waves are transmitted into the concrete, and the reflected signals are received and processed to create an image of the internal structure of the concrete.

GPR can detect various features in concrete, including reinforcing steel, post-tension cables, voids, and cracks. The images produced by GPR can provide valuable information about the condition of concrete structures and help identify potential problems.

Concrete scanning provides a range of specific benefits:

- Safety: Concrete scanning ensures the safety of workers by identifying potential hazards, such as embedded electrical conduits or post-tension cables, before drilling or cutting. This prevents accidental strikes, reducing the risk of electrocution or structural collapse.

- Cost Savings: By accurately locating embedded objects, concrete scanning helps avoid damage to utilities, such as water or gas lines, during construction. This prevents costly repairs, delays, and potential legal liabilities.

- Time Efficiency: Concrete scanning enables efficient project planning and execution. Contractors can identify the precise locations of embedded objects, allowing them to streamline activities like cutting openings or installing new utilities. This eliminates the need for unnecessary exploratory excavations and minimises project delays.

- Preservation of Structure Integrity: Knowing the exact positions of reinforcing steel, post-tension cables, or structural elements within concrete structures helps preserve their strength and stability. Contractors can work around these elements without compromising the integrity of the structure.

- Non-Destructive Testing: Traditional methods of identifying objects within the concrete, such as coring or drilling, can damage the structure and require subsequent repairs. Concrete scanning provides a non-destructive solution, allowing for a thorough examination without causing harm.

- Accuracy and Precision: Concrete scanning technologies, such as ground-penetrating radar (GPR) or electromagnetic imaging, offer high levels of accuracy and precision. They provide detailed information on the location, depth, and size of embedded objects, helping contractors make informed decisions.

- Environmental Friendliness: Concrete scanning minimises unnecessary excavation or removal of concrete, reducing material waste and disturbance to the environment. It aligns with sustainable construction practices by promoting efficient resource utilisation.

By utilising concrete scanning, construction teams can mitigate risks, avoid costly errors, optimise project timelines, ensure structural integrity, and promote environmentally responsible practices. These benefits contribute to overall project success and client satisfaction.

Concrete scanning should be chosen when there is a need to detect or locate embedded objects in concrete structures during construction, renovation, utility installations, structural assessments, demolition planning, historical preservation, or security investigations. It ensures safety, prevents damage, and facilitates efficient project execution.

Concrete scanning can detect and locate various objects and features within concrete structures. Here are some common findings during concrete scanning:

- Reinforcing Steel: Concrete scanning can identify the presence, position, and depth of reinforcing steel bars (rebar) embedded within the concrete. This information is crucial for construction, renovation, and structural assessment purposes.

- Post-Tension Cables: Post-tension cables, used to reinforce concrete slabs and beams, can be detected and located through concrete scanning. This helps ensure their integrity and avoid accidental damage during construction or renovation activities.

- Electrical Conduits and Wiring: Concrete scanning can detect the presence of electrical conduits and wiring within concrete structures. This is important for avoiding accidental strikes during drilling or cutting and for planning utility installations or renovations.

- Plumbing and HVAC Lines: Scanning concrete can help locate plumbing pipes, heating, ventilation, and air conditioning (HVAC) ducts embedded in the structure. It ensures that these systems are not compromised during construction or renovation activities.

- Voids and Voids under Slabs: Concrete scanning can identify voids or air pockets within concrete structures, which can indicate potential weaknesses or areas of concern. It is particularly useful for assessing the integrity of concrete slabs or identifying areas prone to settling or instability.

- Embedded Objects: Concrete scanning can detect various other embedded objects, such as anchors, embedded fasteners, embedded conduits for communication or data transmission, and other hidden features within the concrete.

- Anomalies and Defects: Concrete scanning can reveal anomalies or defects within the concrete, such as delamination, cracks, or areas of deterioration. This information aids in assessing the structural condition and planning necessary repairs or maintenance.

It’s important to note that the specific findings during concrete scanning may vary depending on the technology used, the thickness and composition of the concrete, and the expertise of the scanning operator. The information obtained through concrete scanning helps ensure safety, prevent damage, and facilitate informed decision-making during construction, renovation, or assessment projects.